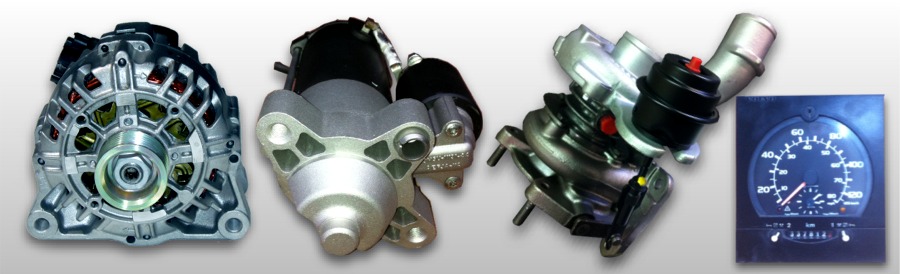

Remanufacturing

Allstart remanufacture on a industrial scale,whether it is large batches or just one unit we can help you.Below the process.

There are many stages that a core (alternator, starter motor or turbocharger) must go through before we call it a remanufactured unit:

- Identification of the core and visual check of the unit

- Disassembly into component parts

- All parts are cleaned thoroughly

- The parts are sorted into those that are suitable for reuse and remanufacture and any that are not suitable for reuse are replaced with new parts.

- The reusable and remanufacturable parts are reconditioned

- The product is reassembled

- The unit undergoes 100% computerised testing to assure performance to Original Equipment Manufacturer (OEM) specifications

We ensure that our remanufacturing process results produces recycled products which are at least as "good as new" and a mark of our belief in our remanufactured products is that we give a 12 months warrenty on material and manufacturing defects.

Remanufacturing is an important form of recycling. It helps reduce energy use and contributes to saving our environment.